Pharmaceutical Manufacturing Software: The Driver for Better Efficiency

In the pharmaceutical manufacturing world, precision and compliance are non-negotiable. Still, small to medium-sized companies (SMEs) and biotech firms often struggle to maintain high-quality production while adhering to strict regulatory standards. The risk of errors—whether it’s a missed step or a compliance issue—is constant and can lead to increased costs, delays, or even legal trouble. Relying on manual processes or outdated systems only exacerbates these challenges. That’s where pharmaceutical manufacturing software makes a difference.

This tool doesn’t just handle the tasks—it does so with the precision that the pharma companies demand. It streamlines production, automates critical tasks, and ensures that every step in the manufacturing process will align with regulatory requirements. Sounds pretty good, doesn’t it? Ready to see how healthcare software development can fix those all-too-common industry issues? Let’s get into it.

from 25 countries outsourced software development to Relevant

We provide companies with senior tech talent and product development expertise to build world-class software.

What is Pharmaceutical Manufacturing Software?

Pharmaceutical manufacturing software manages the complex, highly regulated processes involved in drug and health product production. It doesn’t just keep things organized; it ensures that every step, from production schedules to quality checks, meets the strict regulations and government-mandated requirements of the pharmaceutical industry.

One of the most critical functions of pharmaceutical operation software is its ability to enforce consistency and compliance across all production activities. It meticulously tracks raw materials, monitors each phase of production, and validates that the finished products meet the required quality benchmarks. In this way, it significantly reduces the likelihood of errors that could lead to non-compliance, product recalls, or worse.

Types of Pharmaceutical Manufacturing Software

With the FDA and ICH pushing for faster, digital, and optimized processes, pharma solutions have become essential for modern pharmaceutical manufacturing companies. It has redefined the standards, refining quality management, manufacturing, and resource allocation, influencing the entire drug lifecycle—from R&D to distribution and pharmacovigilance—for those astute enough to capitalize on it.

| Type of Software | Core Functions |

| Enterprise Resource Planning (ERP) Systems | Combines essential business functions—like finance, procurement, HR, inventory control, and production planning—into one system. Helps manage resources efficiently, track transactions, and keep production on schedule. |

| Manufacturing Execution Systems (MES) | Oversees the production process in real-time, from order management to equipment performance. Ensures each step of manufacturing follows the set protocols and keeps track of production orders. |

| Laboratory Information Management Systems (LIMS) | Manages laboratory tasks like sample handling, tracking test results, and lab workflow coordination. Integrates with quality control systems to ensure lab data is used effectively in pharmaceutical production. |

| Quality Management Systems (QMS) | Handles all aspects of quality control, such as document management, deals with non-conformances, and oversees corrective actions. Ensures quality processes are consistent and documented. |

| Supply Chain Management (SCM) Software | Manages the movement of materials and products from suppliers to production and then to customers. Tracks inventory and supplier performance, ensuring materials meet quality standards. |

| Regulatory Compliance Software | Streamlines the documentation and reporting of pharmaceutical manufacturing companies needed to comply with regulatory standards. Manages audit preparation, tracks changes in regulations, and ensures all processes meet current rules. |

Core Features of Pharmaceutical Manufacturing Software

Pharmaceutical manufacturing software comes equipped with a range of features that streamline production, ensure compliance, and uphold the highest standards of quality and safety.

Batch Record Management

In pharmaceutical manufacturing, every detail matters, and missing even the smallest step can have significant consequences. That’s where pharmaceutical industry software steps in, ensuring:

- Accurate and traceable batch records

Pharma industry software creates accurate, traceable batch records, capturing every stage of the manufacturing process. This is essential for product quality, regulatory compliance, and traceability.

- Automated data entry and verification

The pharmaceutical manufacturing ERP software automates data entry and verification, which reduces manual errors and improves data accuracy. This streamlines the batch record creation process and ensures consistency.

Quality Control and Assurance

In an industry where every detail counts, quality assurance isn’t just important—it’s essential. Pharma manufacturing software makes it easier by:

- Real-time monitoring

The tool continuously tracks critical process parameters—such as temperature, pressure, and pH levels—throughout production. This constant vigilance allows for the immediate detection of any deviations from the established norms.

- Integration with QMS for compliance

Integration with a Quality Management System (QMS) ensures that quality control activities align with established procedures and standards, which enhances compliance and efficiency.

Inventory and Supply Chain Management

In a field where every resource counts, effectively managing inventory and supply chains is crucial. Pharma industry software tackles this challenge by:

- Accurate Tracking

With precise tracking of everything from raw materials to finished products, the solution helps maintain optimal inventory levels, reduces waste, and boosts efficiency. It ensures accurate counts, alerts you when stocks run low, and supports effective production planning and cost control.

- Optimized Supply Chain Operations

The tool strengthens the supply chain through direct integration with suppliers and distributors. It simplifies inventory management by automating stock level monitoring, expiry date tracking, and reorder point management.

Regulatory Compliance and Reporting

In an industry where regulations are necessary and complex, compliance is mandatory. Pharma manufacturing software takes the weight off by providing features that ensure adherence to regulations and streamline the path to compliance.

- Meeting FDA, EMA, and Other Regulatory Standards

Pharmaceutical manufacturing faces some of the toughest regulations globally, with bodies like the FDA and EMA enforcing strict standards. The solution is typically designed to meet these high demands, which ensures data integrity, security, and traceability.

- Automated Reporting and Audit Trails

The tool generates reports needed for regulatory submissions, quality reviews, and management reporting. Whether it’s a batch record, a deviation report, or a trend analysis, the software compiles data into clear, concise formats ready for submission.

Data Integrity and Security

In pharmaceutical manufacturing, data underpins every decision. Any compromise—whether due to inaccuracy or a security breach—puts the entire operation at risk, which affects both production and regulatory compliance. Pharmaceutical manufacturing software is essential in protecting this critical asset by:

- Ensuring data accuracy and protection

The software features advanced data integrity tools that uphold the reliability of your data throughout the entire process. It continuously monitors for any signs of corruption or tampering and employs measures to prevent unauthorized access.

- Compliance with Data Integrity Guidelines

Meeting stringent guidelines like the FDA’s 21 CFR Part 11 is not just a regulatory necessity; it’s key to maintaining credibility and operational integrity. The software complies with these standards, ensuring that all electronic records remain secure, accurate, and reliable, with features such as electronic signatures, audit trails, and controlled access integrated to meet these demands.

Production Scheduling and Workflow Automation

It takes more than just good intentions to keep a production line running smoothly—it demands precision and smart resource allocation. Pharma industry solution brings order to the process by:

- Streamlining production processes

The tool removes uncertainty from scheduling, making sure every part of the process operates smoothly. It optimizes resources, cuts downtime, and ensures nothing remains idle or wasted.

- Automation of workflows and resource allocation

Instead of depending on manual tasks that slow progress, the software automates workflows, which allows it to operate more smoothly and quickly.

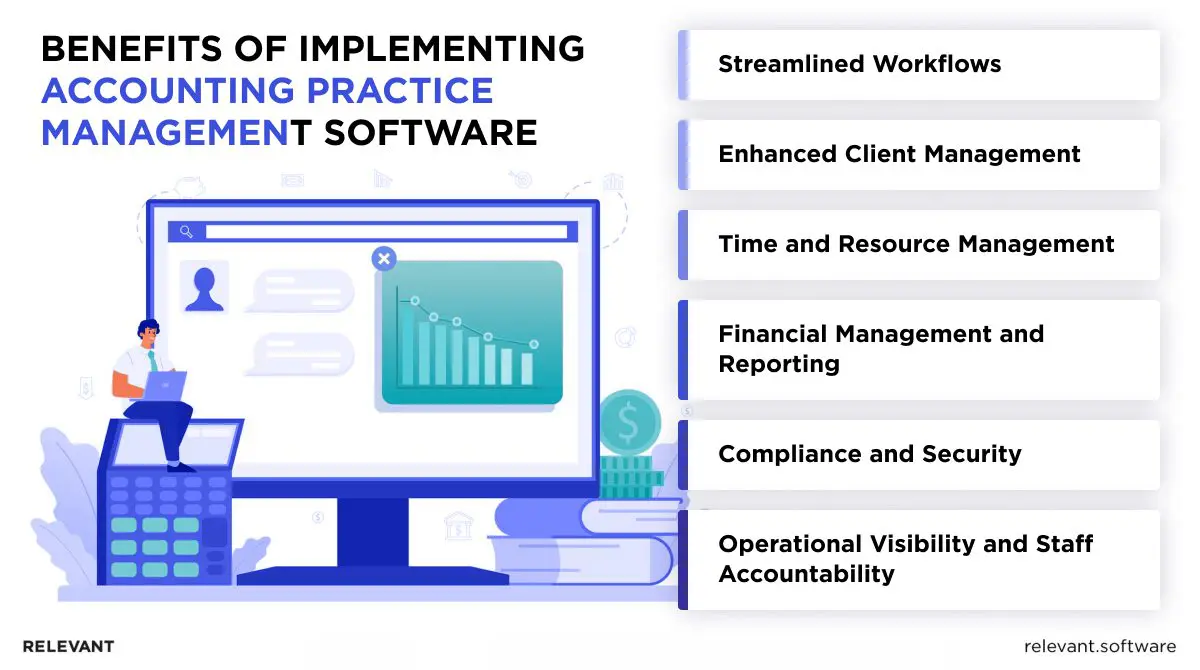

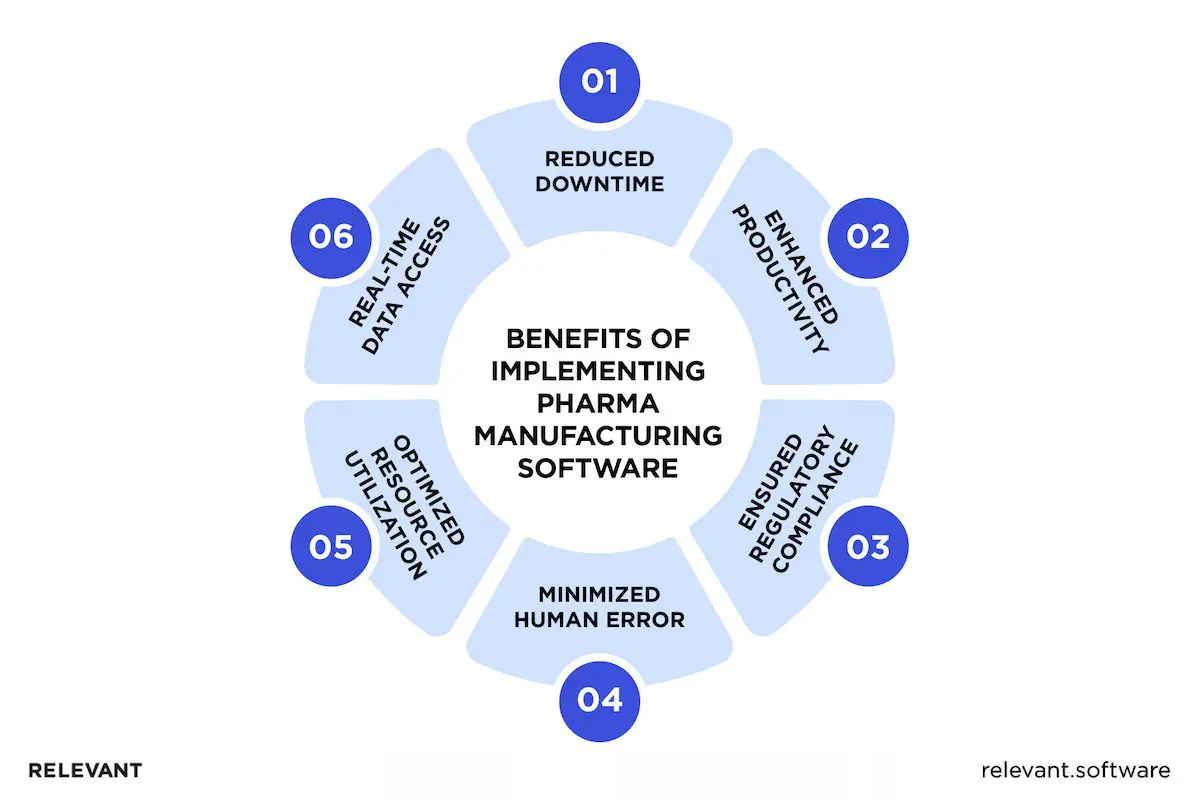

Benefits of Implementing Pharma Manufacturing Software

Implementing such a solution offers substantial benefits, and the numbers prove it. For example, companies that implement advanced pharma software often see up to a 20% boost in production efficiency within the first year. This improvement allows drugmakers to produce products with fewer defects, which ultimately reduces costs and enhances quality for consumers. And that’s just the start—many other advantages arise.

Benefit 1: Reduced Downtime

In pharmaceutical manufacturing, even minor disruptions can have cascading effects on production timelines and costs. Pharma solutions mitigate these risks by offering real-time monitoring and predictive maintenance tools. For example, sensors integrated with the software can detect anomalies in machinery operations, such as unusual vibrations or temperature fluctuations, which may indicate an impending breakdown.

Benefit 2: Enhanced Productivity

Productivity in the pharmaceutical field isn’t just about speed. It requires achieving top efficiency while strictly maintaining quality standards. Pharma industry software enhances productivity by eliminating routine tasks, optimizing resource use, and providing data-driven insights that enable smarter decisions.

Benefit 3: Ensured Regulatory Compliance

Regulatory compliance in the pharmaceutical industry is non-negotiable, with strict standards imposed by bodies such as the FDA and EMA. Tools designed for this sector incorporate regulatory requirements directly into its workflows, ensuring that every step of the manufacturing process adheres to industry standards.

Benefit 4: Minimized Human Error

Human error presents a significant risk in any manual process, particularly in pharmaceutical manufacturing, where even minor mistakes can have serious consequences. Implementing software solutions minimizes this risk by automating many of the critical tasks that operators typically handle. For instance, pharmaceutical ERP software can automate the measurement and mix of ingredients, record batch data, and schedule quality checks.

Benefit 5: Optimized Resource Utilization

Efficient resource management is vital in pharmaceutical manufacturing, where the margin for waste is slim. Likely, specialized tools such as an ERP solution optimize the use of all resources—whether human, material, or equipment—by ensuring that every element of the production process is used to its full potential. For instance, the software can identify potential bottlenecks in the production line and adjust schedules or reallocate resources to ensure smooth operations.

Benefit 6: Real-Time Data Access

Real-time data access provided by pharma manufacturing software allows manufacturers to monitor every aspect of the production process as it happens, ensuring immediate visibility and control from any mobile device. For example, if a particular batch shows signs of deviation from quality standards, the software can flag this in real-time, which enables immediate corrective actions that could prevent a costly recall or regulatory issue.

Challenges in Implementing Pharma Manufacturing Software

Did you know that nearly 70% of software implementation projects in the pharmaceutical industry face delays or unexpected obstacles? This statistic highlights how even the most advanced tools can run into roadblocks when not carefully managed. From integrating with legacy systems to handling the costs and training required, the path to a smooth implementation is often more complex than it first appears. However, with the right strategies, these challenges can be effectively mitigated.

Integration with Legacy Systems

One of the most significant challenges in adopting new pharma manufacturing software is integration with existing legacy systems. Many pharmaceutical companies continue to use older systems that have been in place for years, in some cases decades. These legacy systems often do not have the flexibility or compatibility needed for effective integration.

Solution: To address this, conduct a thorough assessment of your current systems before beginning the implementation. Engage with vendors who offer robust API capabilities or middleware solutions that bridge the gap between old and new systems. Additionally, a phased approach—starting with less critical processes—can help identify and resolve potential issues before they impact core operations. Customization and incremental updates may also be necessary to ensure compatibility without disrupting ongoing production.

Cost of Implementation

The financial investment required for implementing pharmaceutical manufacturing software is often substantial. High upfront costs include software licensing, hardware upgrades, and potential system redesigns. Beyond these initial expenses, concerns about return on investment (ROI) can create hesitancy, especially in smaller companies.

Solution: Begin with a detailed cost-benefit analysis that considers long-term efficiency gains, compliance improvements, and potential reductions in downtime or errors. Consider cloud-based or subscription models that distribute costs over time instead of requiring a significant upfront investment. Also, seek solutions with modular options, enabling you to start with the most critical features and expand as ROI becomes clear.

Is cloud-based or on-premises software more suitable for pharma manufacturing operations?

For pharma manufacturing operations, cloud-based software offers more flexibility and scalability, which is crucial in a dynamic industry. It allows real-time collaboration, remote accessibility, and automatic updates without the need for extensive on-premises infrastructure or maintenance costs.

Training and Change Management

Introducing new software into a well-established environment often meets resistance from staff used to current workflows. Training employees to effectively use the new system is essential but can consume time and incur costs. Beyond the technical aspect, managing change is crucial to addressing the cultural and procedural shifts that come with new tools.

Solution: Create a thorough training program that covers not just technical skills but also the benefits of the new system for daily operations. Engage employees early in the process, gather their feedback, and address concerns to build buy-in. Consider a blended learning approach with hands-on practice, digital resources, and continuous support. A well-structured change management strategy that clearly conveys the advantages of the new system, along with phased implementation, can greatly reduce resistance and improve adoption.

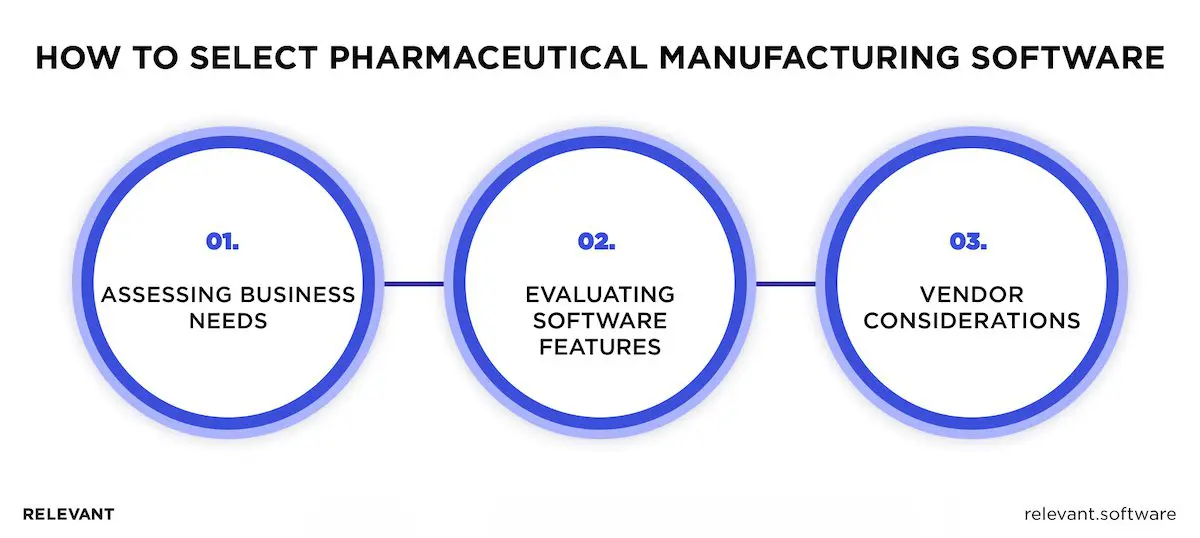

Selecting the Right Pharmaceutical Manufacturing Software

There are already many ready-made solutions on the market, and sorting through these choices to find the right option can feel overwhelming. To help you make an informed decision, we’ve put together a quick guide on how to choose the best tool for your needs.

Assessing Business Needs

The first step in pharma manufacturing software selection involves a thorough assessment of your business’s specific needs and goals. Understanding the unique challenges your operation faces, whether related to compliance, production efficiency, or quality control, is crucial. This assessment should align the software’s capabilities with your long-term objectives. It ensures that the solution not only addresses immediate concerns but also supports future growth and scalability.

Note: A good software solution should not just solve today’s problems but also support your long-term goals. Custom solutions often excel here because they’re tailored to fit exactly what you require and can adapt as your business grows.

Evaluating Software Features

Carefully evaluating the features of each pharmaceutical software option against your business requirements is essential. Not all solutions offer the same functionalities, so it’s important to identify those that best align with your operational goals. For instance, if your focus is on enhancing quality control, look for options with robust quality management tools. Similarly, if compliance is a top priority, the software should offer comprehensive reporting and audit trail capabilities.

Note: Custom solutions tend to shine here because they can be built around the specific features you need, making them a better fit for your operation.

Vendor Considerations

Selecting a software vendor goes beyond the product itself; it involves an assessment of the vendor’s support structure, reputation, and ability to scale with your business. The vendor’s reliability and customer service can greatly influence the implementation process and constant support. Also, consider the vendor’s capability to provide scalable solutions that grow with your company, which ensures the software continues to meet your needs as your operations expand.

Note: Custom solutions from a reputable vendor are often more scalable, meaning they can evolve with your company. This flexibility makes custom solutions a stronger long-term choice compared to off-the-shelf options.

Pharmaceutical Manufacturing Software: Final Thoughts

In the complex world of pharmaceutical manufacturing, the right software isn’t just a nice-to-have—it’s a necessity. It drives efficiency, ensures compliance, and upholds the highest standards of quality. But here’s the thing: one-size-fits-all software often doesn’t cut it. Your business is unique, and your software should be, too.

That’s where we come in. We don’t believe in cookie-cutter solutions. Our custom-developed software is designed specifically to fit your business, addressing your exact challenges and helping you stay ahead of the curve. Being recognized as a top software development company on Clutch isn’t just a title for us. We’ve successfully completed many custom healthcare projects, and our clients are thrilled with the results, so you can count on us to do the same for you.

When you choose our pharmacy management software development services, you get a team dedicated to your success, fully prepared to create solutions that genuinely meet your needs. Contact us!

Hand-selected developers to fit your needs at scale! Let’s build a first-class custom product together.