From Vision to Reality: Unleashing the Value of Digital Twin Benefits

Imagine if you could clone your business. Not just the brick-and-mortar element of it but every last process, decision, and asset. Picture having an exact replica where you can test and tweak strategies without risking real-world consequences. It sounds like something straight out of a sci-fi movie, right? Well, it’s called a digital twin, and it’s revolutionizing product development, transforming the way we develop, test, and refine products.

If you think this is just another tech fad, it’s not. Recent research suggests that the hype around digital twins is well-founded. Only 5% of surveyed executives not considering it as part of their digital transformation strategy, and a whopping 86% view it as a viable investment. Digital twins are here to stay. With this technology, you can try out new ideas, test new strategies, and predict future scenarios without disturbing your real-world operations.

200+ companies from 25 countries outsourced software development to Relevant

We provide companies with senior tech talent and product development expertise to build world-class software. Let's talk about how we can help you.

Contact usCurious to know more? Then keep reading to learn what is a digital twin, its benefits, its applications, and what you should consider before adopting one.

Table of Contents

What Is Digital Twin Technology?

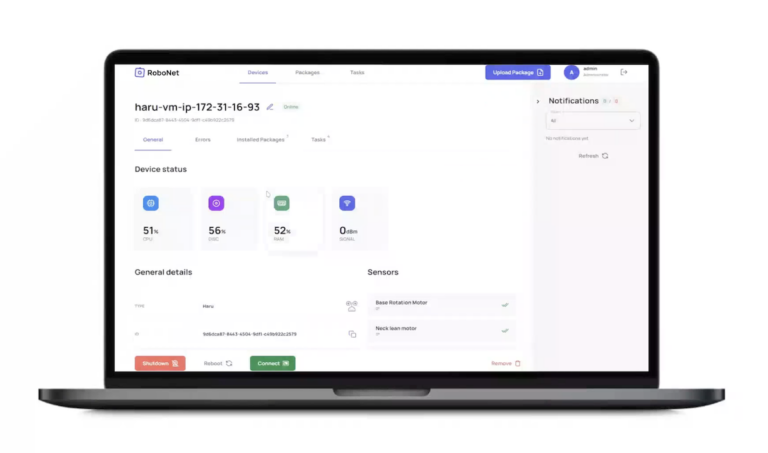

Digital twin technology, in a nutshell, creates a dynamic, virtual model of your business environment, product, or system that reflects your business operation in real time. The secret sauce of a digital twin lies in its connection to real-time data streams. This unique feature sets it apart from regular 3D models and simulations. Armed with sensors and powered by the Internet of Things (IoT), a digital twin gathers and analyzes data, evolving alongside its real-world counterpart.

Your digital twin lives and breathes with your business. As your operations shift and evolve, so does your twin. It’s like having a customizable blueprint of your business that not only tells you what’s happening now but can also check future performance and assess potential risks.

What’s more, a digital twin concept is currently attracting the interest of business leaders due to its ability to predict, analyze, and simulate different situations and conditions. It allows you to experiment and validate new ideas without risking your actual operations or before developing a real product. Moreover, you can build a component digital twin or process digital twin, making it as simple or complex as you need it.

The Digital Twin Market Stats You Can’t Ignore

Grand View Research revealed that the digital twin market was worth $11.12 billion in 2022, with the automotive, manufacturing, and aerospace industries leading the way. And it’s projected to grow annually at 37.5% from 2023 to 2030.

The reports show that digital twins are playing a leading role in shaping the future. So, let’s dive into some more data.

By 2028, it’s predicted that over 94% of all IoT platforms will incorporate one or another form of digital twin capability. Yes, you read that right. Digital twinning is set to become a standard feature for IoT Application Enablement in less than a decade. Furthermore, more than 96% of executives in industrial sectors see the need for integrating IoT with digital twin functionality.

But what about business leaders?

Over 42% of business leaders across diverse industries realize the benefits of a digital twin. Even more impressive, 59% of them plan to incorporate digital twins within their operations by 2028. Those who already adopted digital twins applied it for asset twinning, component twinning, system twinning, and process &workflow twinning. That’s right, digital twins are being used to replicate and improve virtually every aspect of business operations. Business leaders note particular values and opportunities of a digital twin in manufacturing.

The numbers speak for themselves. The digital twin market is booming, and businesses worldwide are racing to harness its potential. After discovering digital twin benefits, there would be something to think about.

Key Benefits of the Digital Twin

From efficiency gains to cost reduction, from streamlining processes to mitigating risks, this cutting-edge technology is transforming how we do business. So, let’s review in detail the advantages digital twin technology offers.

Enhanced Real-Time Monitoring and Analytics

The digital twins are your ticket to a level of real-time monitoring and analytics that was previously unthinkable. Think of it as having your personal command center accessible anytime, anywhere.

Monitoring a vast physical system in real-time is like trying to keep an eye on every grain of sand on a beach. But with a digital twin, you have a virtual version of that system, making monitoring effortless.

So, how can this help you?

Picture this: You’re sipping your morning coffee when a notification from your digital twin manufacturing pops up. One of your machines is showing signs of wear and tear. So instead of waiting for the machine to break down, you order a replacement part then and there, averting a costly production halt.

And that’s just one machine. Scale that up to your entire operation, and you’re looking at a game-changing level of oversight. Real-time monitoring with a digital twin gives you the most up-to-date information on your assets, enabling you to make informed decisions at lightning speed. This isn’t just about preventing problems. It’s also about seizing opportunities. Real-time analytics of your process digital twin can help you spot trends, identify efficiencies, and make data-driven decisions that could transform your business.

Accelerated Product Development and Testing

So, you’re planning a new product. But instead of going through the usual time-consuming and costly cycle of prototype, test, tweak, repeat, you create a digital twin of your planned production process. This virtual sandbox allows you to test and validate your product before it even exists in the real world.

Digital twins offer unprecedented insights into how systems interact and potential failure modes. This means you can skip the exhausting test-and-repair loops, saving time to get your product production-ready.

And here’s the icing on the cake: digital twins provide continuous insights into your products’ performance in the field. This feedback loop allows you to iterate and innovate faster and more efficiently. No more guessing, no more costly mistakes.

And if it’s still not convincing, here’s more. When paired with digital models and simulation tools, you can test and analyze product performance before you start building a physical prototype. This can result in great time and resource savings, especially for high-cost products. Late-stage redesigns? A thing of the past. Reduced time-to-market? You bet. With the pace of innovation hitting lightning speed, these benefits of digital twin technology are a game-changer.

Improved Decision-Making and Risk Management

By leveraging a digital twin, you can get a real-time, in-depth understanding of your system’s performance. This isn’t just a snapshot; it’s a live, dynamic view. This means you can make data-driven decisions based on what’s happening now rather than what happened last week, last month, or last year.

Think of a digital twin as a safe testing ground. You can simulate different scenarios, assess the potential impacts, and devise appropriate strategies without risking real-world fallout. Unexpected system behavior? You can catch it in the digital twin first.

Engineers can shake things up with a digital twin, simulating unexpected scenarios to see how the system reacts. This not only enhances risk assessment but also helps identify mitigation strategies. So, you’re not just responding to issues; you’re proactively identifying and addressing them. This proactive approach significantly improves risk management and allows you to navigate with confidence.

Better decision-making and risk management mean fewer costly mistakes, less wasted time, and more efficient operations. In short, digital twins can improve your profitability and give you a competitive edge.

Optimized Maintenance and Support

Thanks to the magic of digital twins that can predict and address maintenance needs, you can easily turn potential headaches into minor speed bumps. The continuous flow of information allows the digital twin to forecast when and where issues might occur long before they become critical.

Traditionally, businesses get used to reactive maintenance: something breaks, and you fix it. But what if you could know beforehand when a component is about to fail? That’s precisely the edge a digital twin offers. It shifts your maintenance strategy from reactive to proactive, minimizing downtime and saving you money.

With a digital twin, your support team can troubleshoot issues in a risk-free environment. They can simulate solutions and predict their outcomes, ensuring the chosen fix is the best option before it’s implemented in the real world.

So, you can optimize maintenance and enhance support, leading to more efficient operations, happier customers, and, ultimately, a healthier bottom line. You can turn the unpredictable into the predictable and keep your business running smoothly.

Facilitated Collaboration and Knowledge Sharing

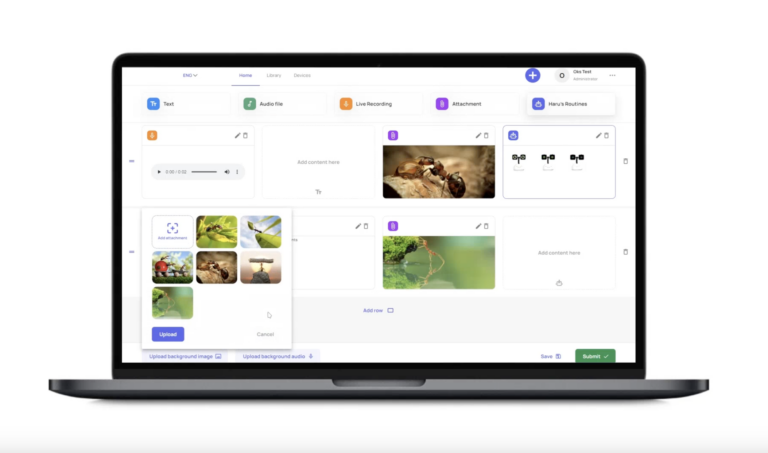

Digital twins offer an interactive, virtual environment where your team can work together seamlessly. A platform where every design, idea, and insight can be shared and developed in real-time. Digital models provide instant, round-the-clock access to system information, freeing your team to focus less on manual tasks and more on what truly matters.

The unique ability of digital twins to manage vast quantities of data across various deployments coupled with AI-powered software solutions can handle feedback from your whole ecosystem. They can highlight critical issues during product development and provide proactive input to all members of your team, creating a collaborative environment that transcends traditional boundaries.

By creating an immersive environment, digital twins allow your team to visualize and test ideas in ways that would initially be too expensive or impractical in the real world. Imagine engineers and designers exploring a virtual vehicle, tweaking its design, and validating their ideas without ever stepping foot in a garage. That’s the power of digital twins! For example, Volvo Cars use digital twin models for the entire product lifecycle, including product design, R&D, and consumer-focused applications.

Personalized user experience

In today’s marketplace, delivering a personalized experience can set you apart from the competition. And a digital twin can help you enhance client satisfaction. The virtual model collects real-time product usage data, helping you better understand your customers’ needs.

Here’s the exciting part: with digital twins, you can predict maintenance needs, streamline customer service, and enhance repair operations. Imagine being able to address a product issue before your customer even realizes it’s there! That’s next-level customer service.

On top of that, the data digital twins collect can inform future product enhancements, helping you to stay ahead of the curve and deliver a product that exceeds customer expectations.

Digital twins in healthcare and logistics, aerospace and defense, industrial machinery, and manufacturing show great results in delivering personalized user experiences. In fact, any business can enjoy these digital twin benefits to unlock customer loyalty and drive business success.

Digital Twin Applications in Various Industries

Digital twin technology is so versatile that it could transform any industry, from manufacturing to energy, automotive, and even logistics. So, let’s explore how digital twins are shaping various industries.

Manufacturing

Digital twins allow you to simulate an entire production process from start to finish, identifying potential hiccups and optimizing every stage. This is a real benefit of a digital twin in manufacturing. With a factory digital twin, you can visualize the lifecycle of a product before it’s even made. This foresight allows you to catch errors before they occur, saving time, reducing costs, and ultimately boosting your bottom line.

Energy

Twin models can predict behaviors that optimize energy production powers, analyze vast amounts of data, and model the performance of power plants. The technology acts as a virtual reflection of your operations, helping to spot energy demand, cut down on the costs for new plant setups, and make better decisions when it comes to energy storage. In short, digital twins can light the way to a more efficient and cost-effective energy industry.

Automotive

Think about a production process that minimizes errors, identifies potential bottlenecks, and shortens development time. With digital twins, this is the new reality for the automotive industry. These virtual models simulate behaviors and predict possible failures, ensuring smoother production and a high-quality final vehicle. The result? Cost savings, reduced errors, and an accelerated road to success.

Logistics

Digital twins in logistics can simulate the flow of materials and people, improving and optimizing logistics processes. With twinning technology, you can capture every stage of the process and simulate various scenarios. This insight provides valuable information for decision-making, allowing you to make the most appropriate choices in each situation.

Final Thoughts

No matter your industry or unique business needs, the digital twin use case can offer a transformative advantage. From increasing operational efficiency in manufacturing to reducing defects and shortening production times, the benefits of digital twin technology are plentiful. Imagine having the ability to anticipate potential problems, optimize processes with real-time information, and significantly decrease unplanned downtime.

As enticing as they sound, digital twins aren’t a switch you can flip on overnight. You need the right ingredients – in this case, a tech partner with deep expertise in data analytics, cloud computing, and machine learning. Setting up your digital twin platform can be a complex process, but with the right team on your side, the possibilities are boundless.

That’s where we come in. Our team at Relevant Software is equipped with a comprehensive understanding of the technologies that drive digital twins – from data analytics to artificial intelligence and machine learning. Our expertise extends to virtualization, cloud, IoT devices, wireless modules, and beyond. We’re not just here to deliver advanced solutions; we’re here to customize these solutions to help your business thrive in the digital age.

FAQ

Our core services:

Do you want a price estimate for your project?

Do you know that we helped 200+ companies build web/mobile apps and scale dev teams?

Let's talk about your engineering needs.

Write to us