Enterprise director interface

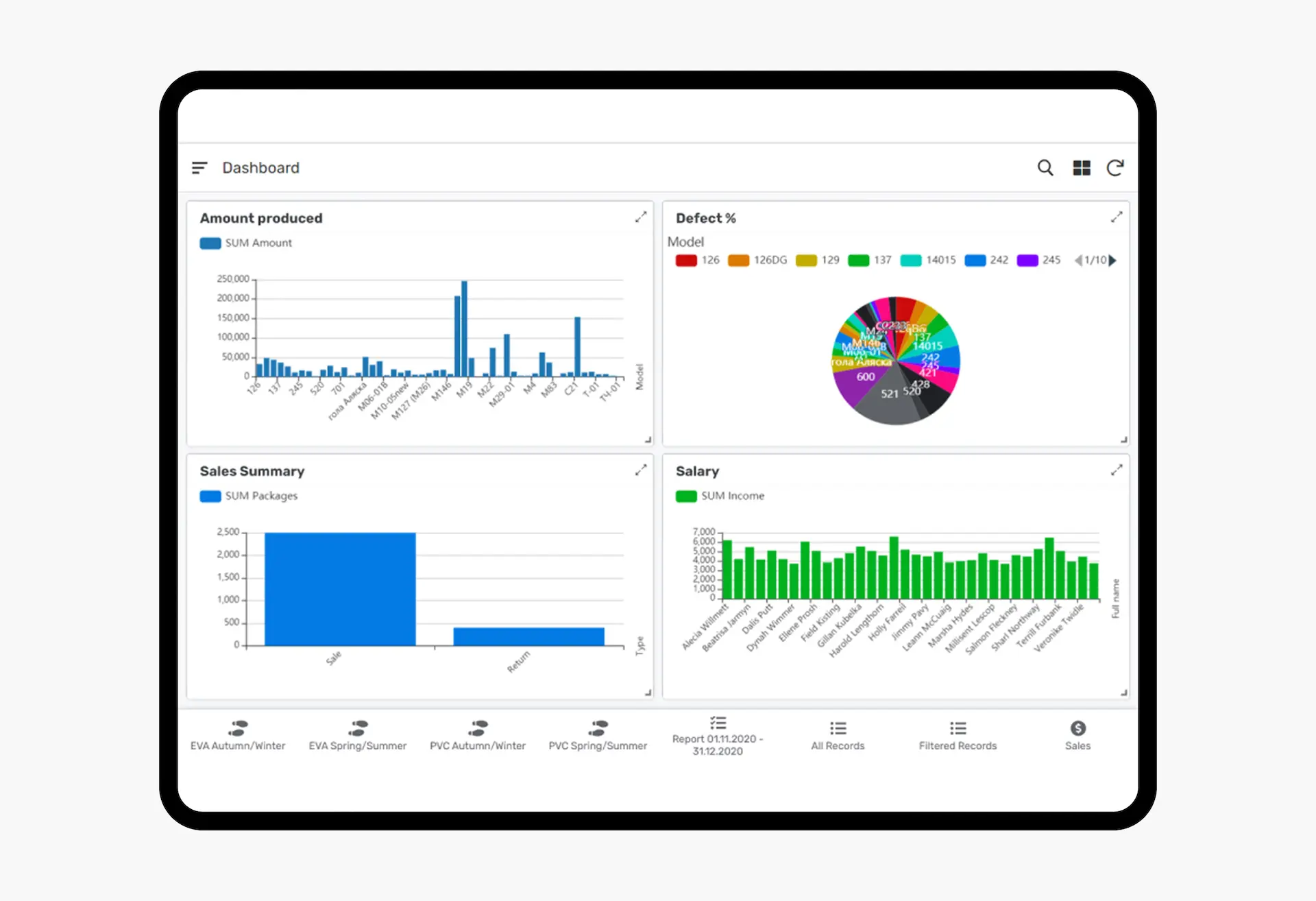

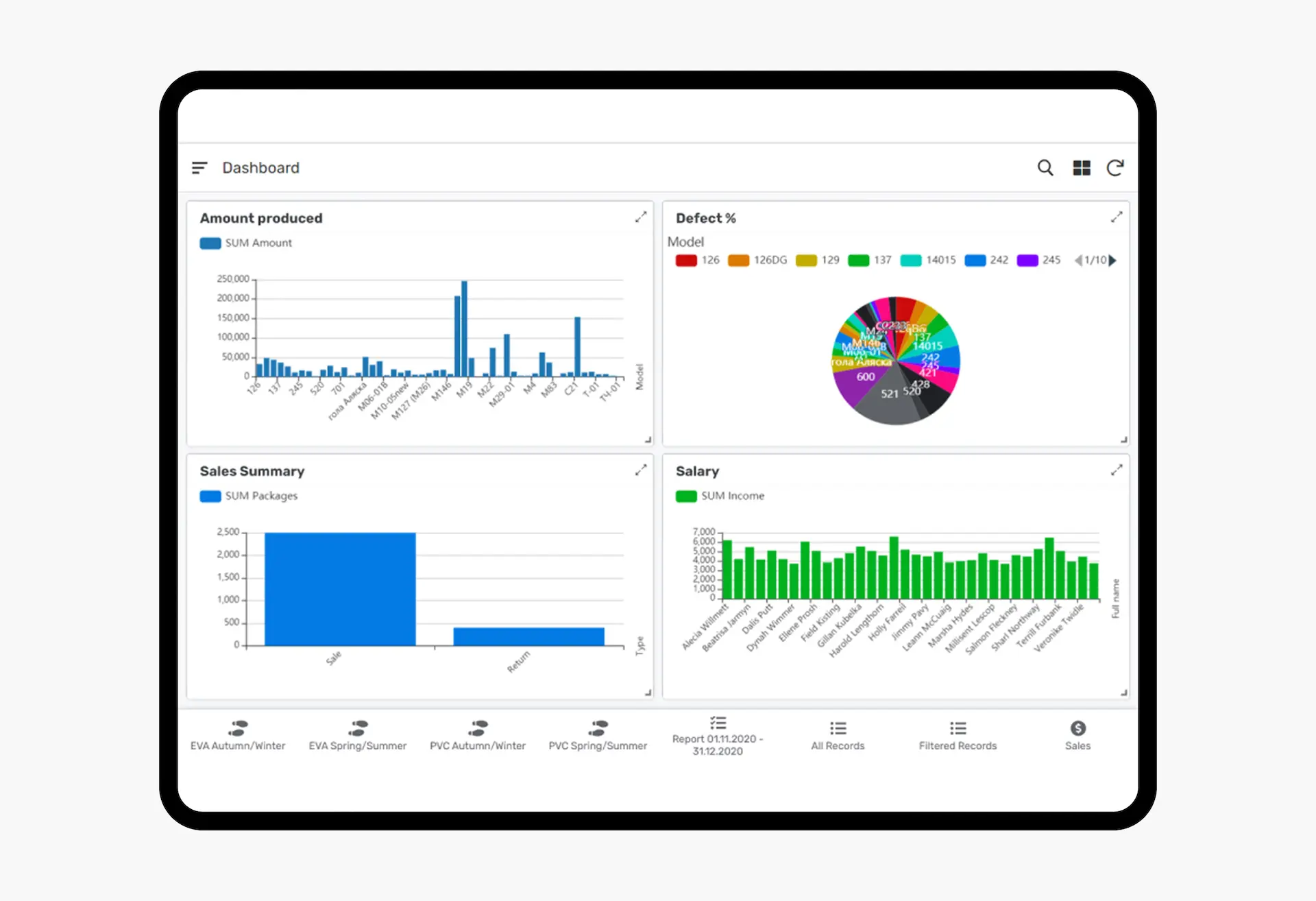

Our team delivered a dashboard showing total ready models in the warehouse and active tasks across all shops. This enables executives to monitor production status at a glance.

Hours saved per week by shop managers

30 hImprovement in data accuracy

85 %Production lines that are fully digitized

5 linesDago Style, a Ukrainian footwear manufacturer, relied on manual shift reports to track production. At the end of each shift, workers submitted paper forms, and shop managers spent nearly a full working day each week transcribing that data into spreadsheets. This outdated method created bottlenecks, introduced inconsistencies in product naming, and made it difficult to detect defects in time. Leadership lacked a reliable, centralized view of ongoing tasks, quality issues, and inventory levels.

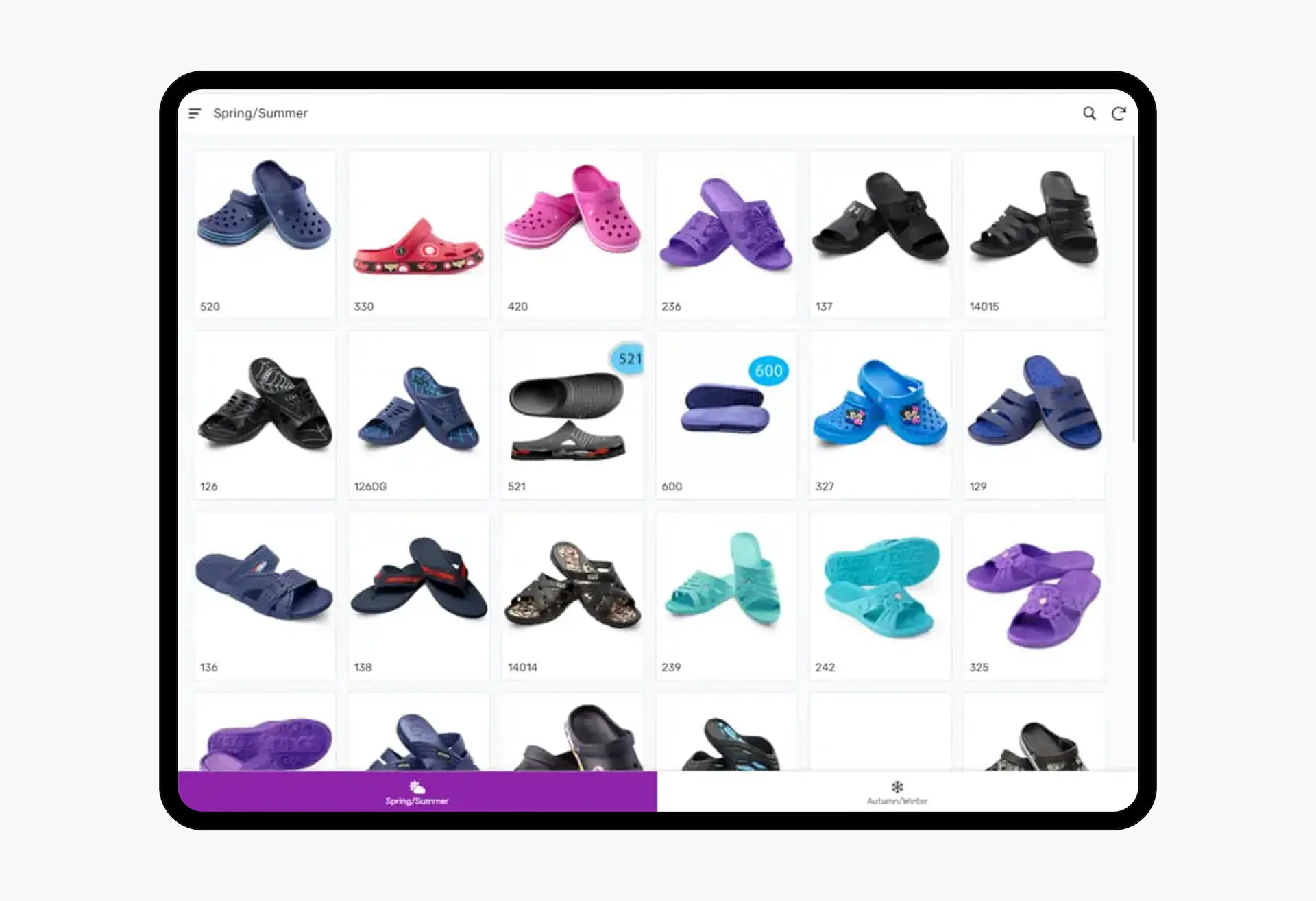

To overcome these limitations, the company needed a digital platform that would allow workers to submit production figures electronically, enforce standardized naming, and track defects in real time. The solution had to consolidate all this data into one system accessible to every role, from the shop floor to executive management.

To bring this vision to life, Dago Style chose Relevant Software. They picked us because of our strong track record in low-code development and custom solutions for manufacturing. Our team had solid experience with AppSheet and cloud infrastructure, communicated clearly, delivered high-quality results, and always met deadlines. That made us the right partner for their digital transformation.

Production manager at Dago StyleThe prototype allowed us to validate workflows before full deployment. We identified process gaps early and avoided costly rework.

Our team delivered a dashboard showing total ready models in the warehouse and active tasks across all shops. This enables executives to monitor production status at a glance.

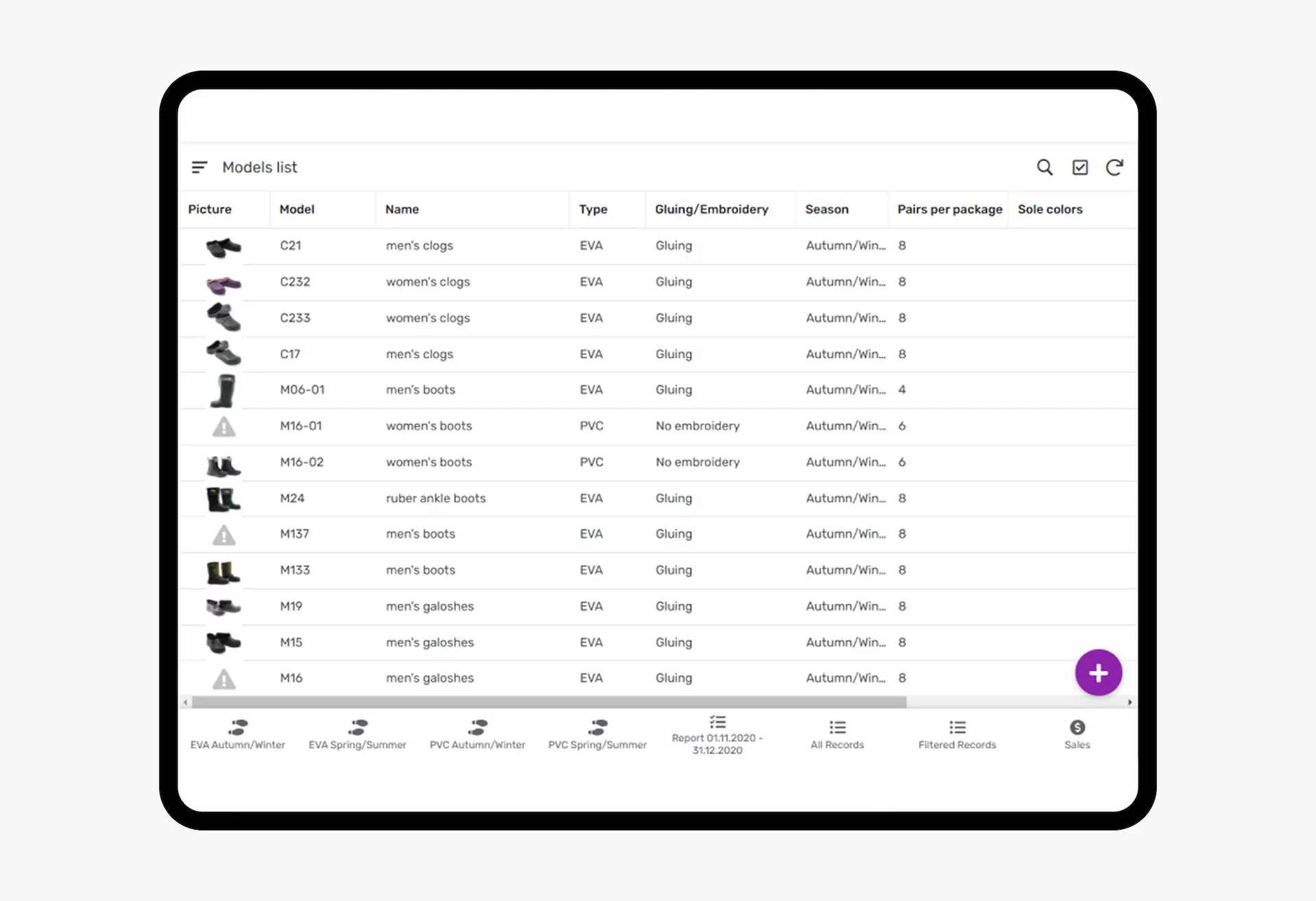

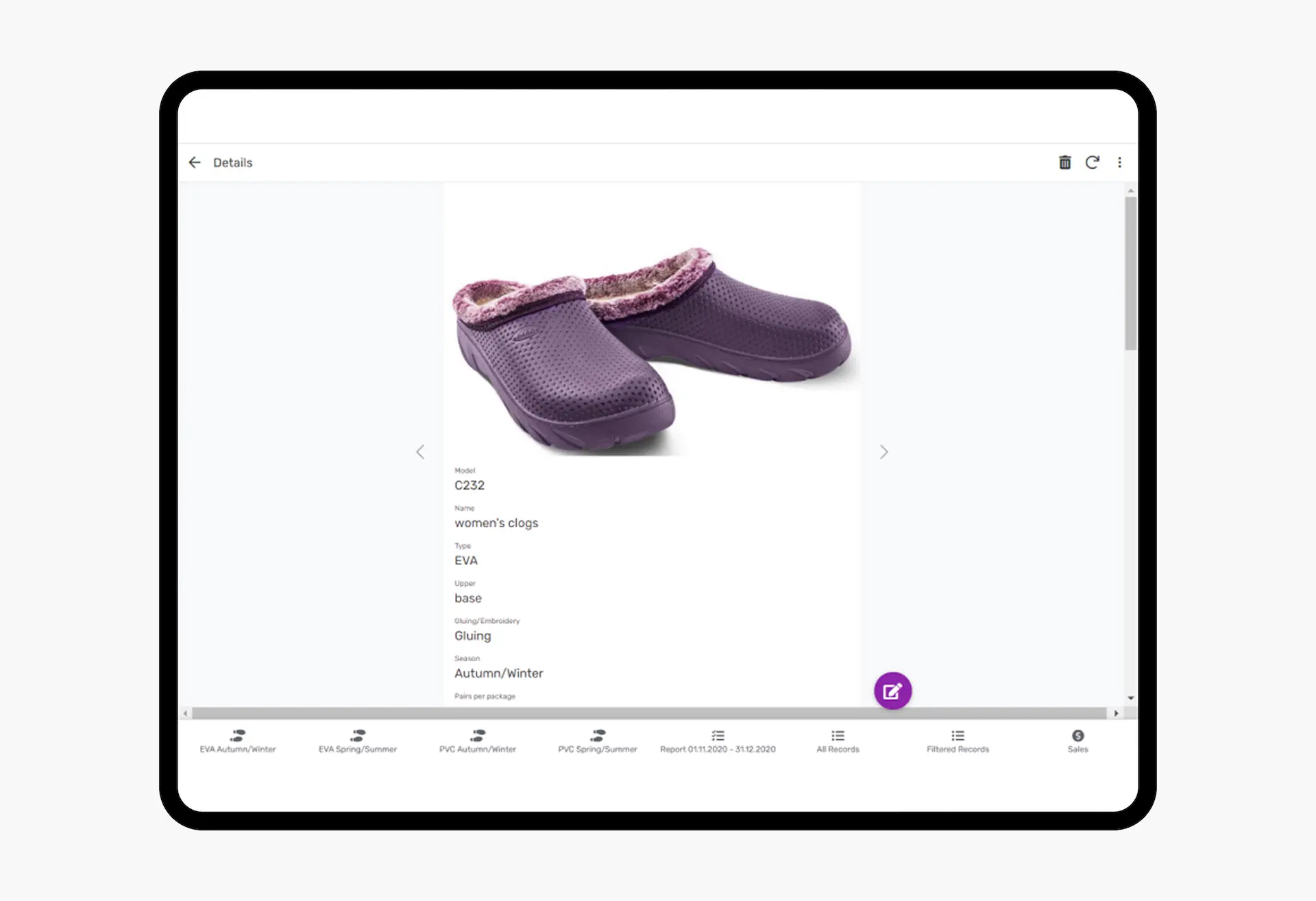

Our engineers built a control panel that allows administrators to add or modify shoe models, manage user accounts, and permissions. This helps employees view tasks per shop and machine, track defect counts, and receive alerts when production deviates from set norms.

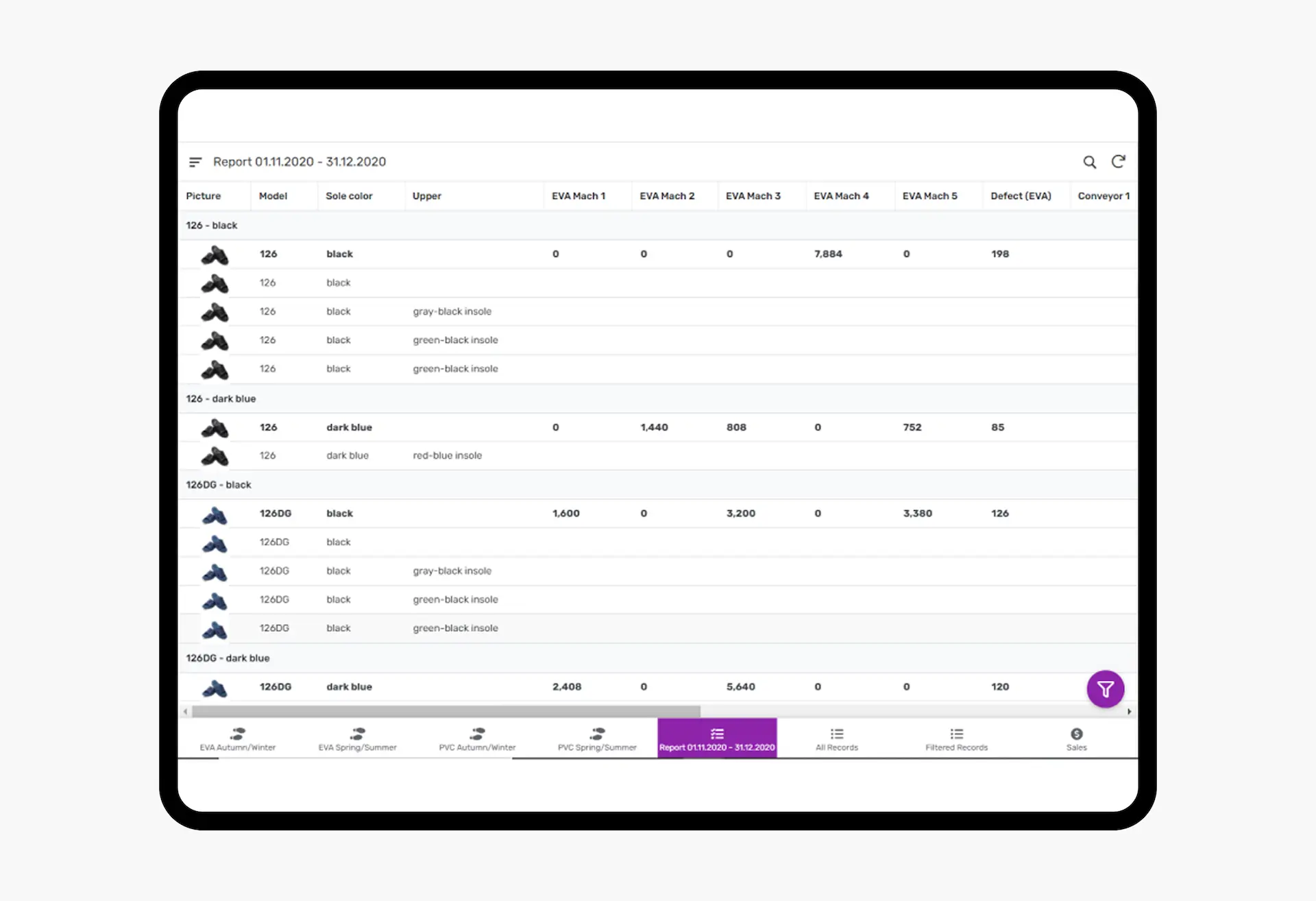

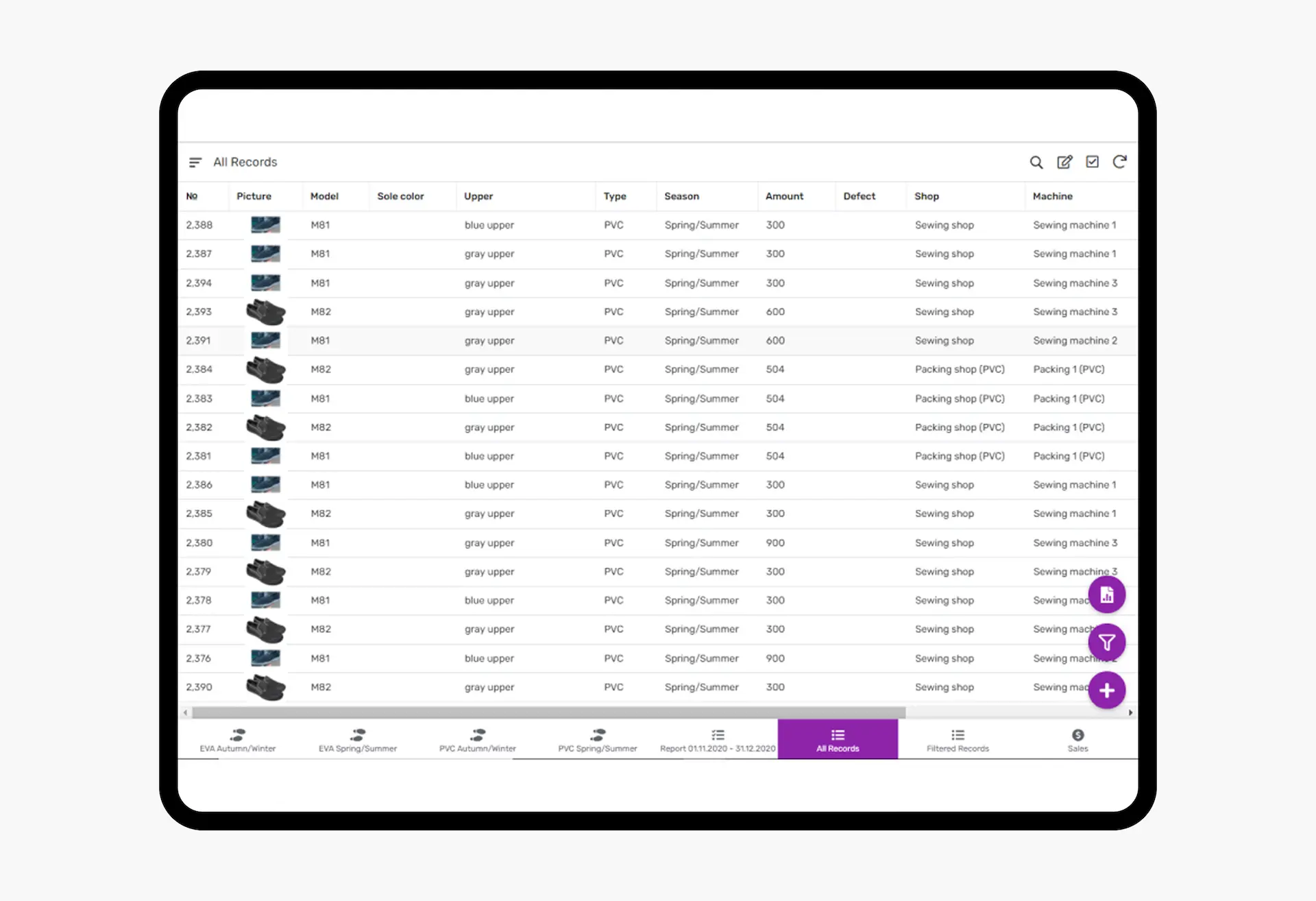

We created a portal for masters to assign tasks by machine, set priorities, pause operations, and generate reports on output per employee. This provides real-time insight into shop performance.

The team implemented a simplified interface for workers to view their assigned machine tasks and report the number of items produced per shift. This replaces paper-based reporting and improves data consistency.

Our developers delivered a view that displays the current warehouse inventory and items in production. This lets sales teams accept orders in advance and prevent stockouts.

This component allows warehouse managers to log outgoing shipments and sold items in real time. It keeps stock levels accurate and up to date across all departments.

75 % reduction in reporting time

Digital entry forms replaced pen-and-paper transcription, freeing managers from 120 hours of manual reporting each month and accelerating access to production data.

90 % fewer false inputs

Standardized product naming and structured data capture eliminated inconsistencies and reduced data-entry errors, ensuring accurate defect tracking at every stage.

Full rollout across five lines in 2 months

The AppSheet prototype validated workflows on one line; within eight weeks, the solution scaled to all five production lines on Google Cloud, providing enterprise-wide visibility.

✓ Built an AppSheet prototype with standardized data-entry forms

✓Created dashboards and alerts for instant task and defect status

✓Set up user roles so that each interface displayed relevant screens

✓Conducted stakeholder interviews and delivered a clickable prototype in three weeks

✓Migrated data to Google Cloud and rolled out the solution to all production lines

Production manager at Dago StyleWe’re saving over 120 hours every month, spotting issues faster, and finally have full visibility across all five lines. The team not only met our expectations — they exceeded them. This was one of the most seamless and impactful transformations we’ve experienced.

Share details about your project and book a free call with us

to discuss your development strategy