Remote Temperature Monitoring: Key Benefits and Applications

Surprising but true: A tiny two-degree fluctuation in temperature can turn a million-dollar shipment of goods into a costly disaster. In the pharmaceuticals, food storage, and logistics world, it doesn’t take much to spoil an entire shipment, derail safety protocols, and throw supply chains into chaos. Given what’s at risk, a remote temperature monitoring system isn’t something you can skip—it’s something you need.

Wondering what practical benefits these systems offer? And where can you develop one for your company? Explore our story to learn how IoT software development could help you stay on top in your industry (where the view’s always better).

from 25 countries outsourced software development to Relevant

We provide companies with senior tech talent and product development expertise to build world-class software.

What is Remote Temperature Monitoring?

Remote temperature monitoring involves overseeing environmental conditions from a distance. This technology makes sure your temperature-sensitive products stay within the right limits, helping you avoid spoilage, damage, and any unwanted attention from regulators.

But how exactly does it do that? It all begins with sensors strategically placed in the environment or equipment you need to monitor. These sensors constantly gather data and send it to a centralized system through wired or wireless networks. Collected data is accessible from any place via cloud platforms, which allows users to monitor, analyze, and make decisions in real-time with the help of instant alerts and probes.

Milestones in the Technology’s Evolution

The evolution of remote temperature monitoring technology has seen several key milestones. From the early days of basic manual checks to today’s advanced, automated systems, each step forward has made this technology more accurate, reliable, and accessible.

| Milestone | Description |

| Early Systems | These relied on manual data collection and wired connections and were limited in scope and flexibility. |

| Wireless Communication | The transition from wired to wireless sensors expanded reach, with deployment in remote and inaccessible locations. |

| Advancements in Sensor Technology | With sensors becoming more accurate and energy-efficient, these systems now perform at a much higher level. |

| Sensor Miniaturization | Miniaturized sensors allowed integration into various devices and environments, especially for monitoring temperature and humidity levels for optimal conditions. |

| Integration with IoT | IoT enabled the interconnection of devices with intelligent networks for extensive data collection and analysis. |

| Integration with Cloud Computing | Provided infrastructure for data storage, processing, and analysis, which were suitable for advanced analytics and predictive capabilities. |

For more insights, check out our overview of what IoT is.

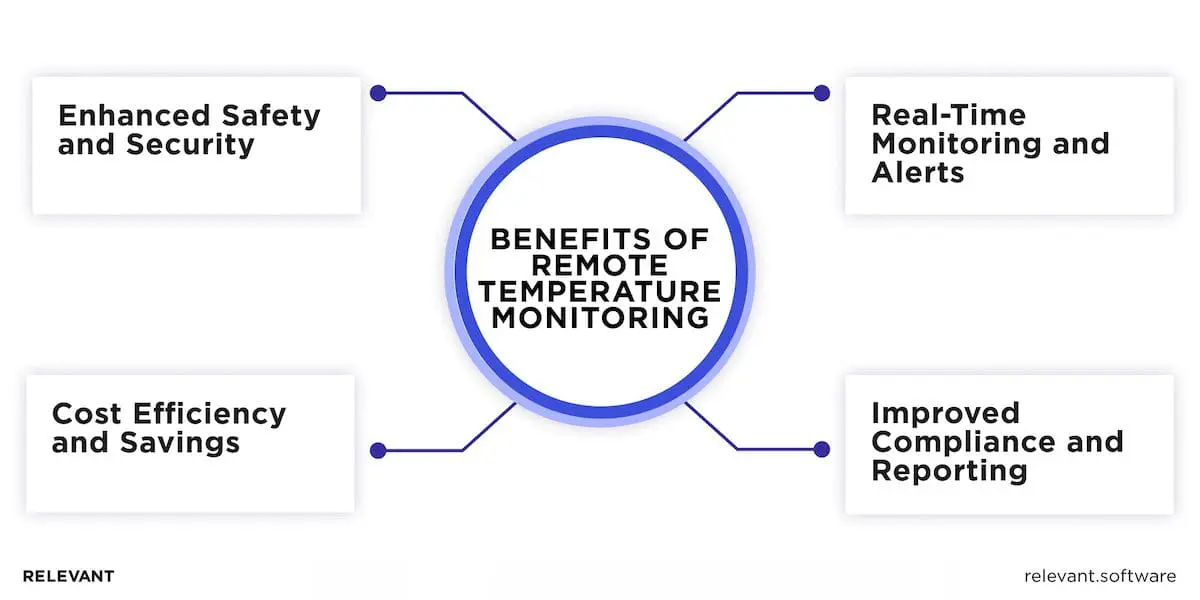

Key Benefits of Remote Temperature Monitoring

Remote temperature monitoring systems offer many benefits —they are essential tools for enhanced safety, greater efficiency, and assured compliance. They take a big weight off your shoulders, plain and simple.

Enhanced Safety and Security

Data show that equipment or heat-source failure accounts for roughly a quarter of structure fires at industrial properties, rising to about 31% in manufacturing facilities. Remote temperature monitoring significantly reduces this risk by offering constant oversight, which prevents hazards before they escalate. These systems keep temperature-sensitive products safe throughout transit and storage, safeguarding both the goods and your bottom line.

For example, in healthcare, IoT technology can monitor hospital environments 24/7 to maintain safe conditions for patients. High-temperature sensors boost safety and security by alerting users right away to any dangerous temperature changes. This is crucial for such assets as production facilities, commercial ovens, furnaces, and boilers that need precise and consistent temperatures.

Cost Efficiency and Savings

One of the main benefits of remote temperature monitoring is, surprisingly, cost savings. By optimizing temperature control, energy waste is minimized. And with predictive analytics, potential issues are spotted early, which prevents costly repairs later. As discussed in our article on IoT in manufacturing, this kind of monitoring helps streamline operations and reduce costs.

Real-Time Monitoring and Alerts

Another advantage of this technology is being able to access data instantly and get real-time alerts. For instance, in critical situations like a sudden freezer malfunction in a pharmaceutical storage facility, real-time monitoring, alerts, and audits can make all the difference between preserving valuable stock and losing it. This level of oversight provides peace of mind for business owners.

Improved Compliance and Reporting

Remote temperature monitoring simplifies the process for businesses to adhere to industry standards and regulations. The system automatically tracks and logs temperature data, removing the report hassle and ensuring you’re always prepared for the auditing process. This keeps you compliant and in good standing with clients and regulators. This is especially important for agriculture and healthcare, where proper storage temperatures in fridges and freezers are crucial for food and vaccine safety.

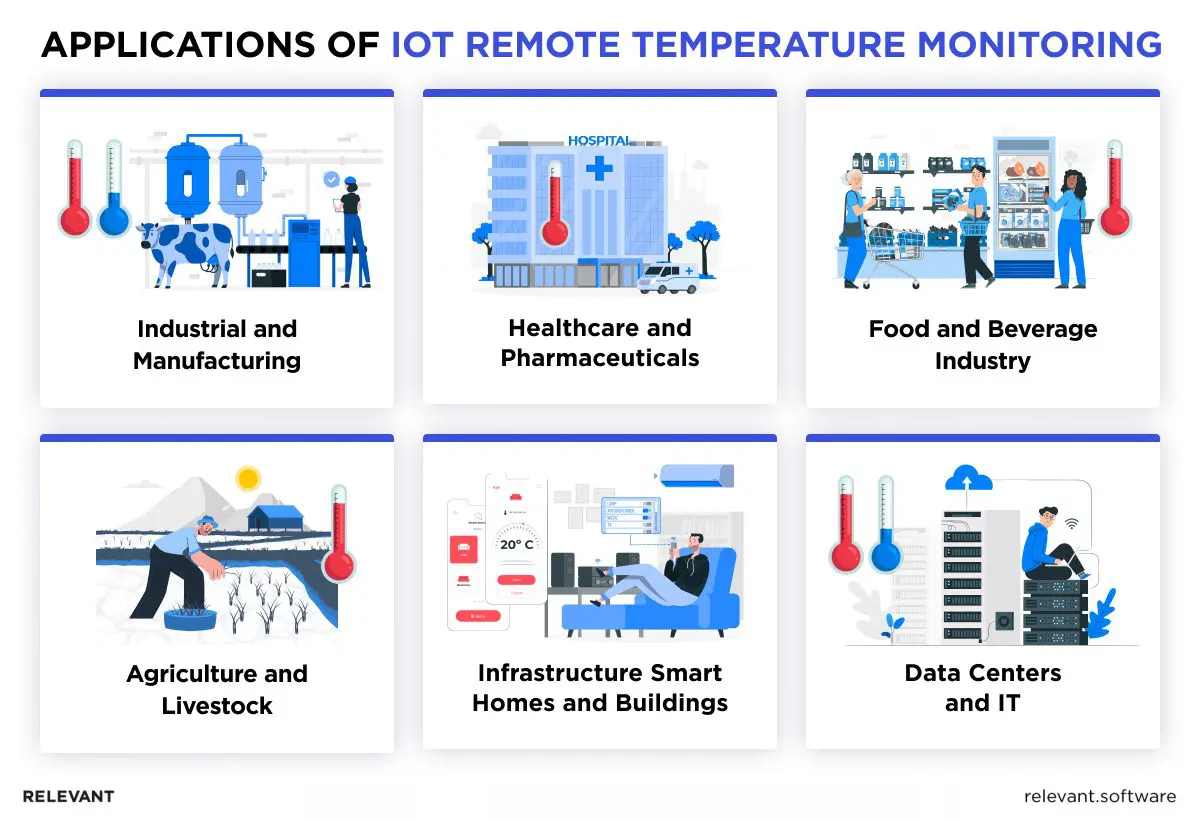

Applications of IoT Remote Temperature Monitoring

Remote temperature monitoring is not limited to one sector. Its applications span multiple industries where precise control is critical – from tracking factory equipment to monitoring remote buildings and everything in between.

Industrial and Manufacturing

In industrial environments such as automotive manufacturing, keeping machinery from overheating is crucial throughout production. For example, IoT in manufacturing allows a car assembly plant to use remote monitoring to keep robotic welding machines within safe operating temperatures. This prevents costly downtime due to equipment failure.

Healthcare and Pharmaceuticals

In the pharmaceutical industry, maintaining the correct temperature is critical, for instance, for vaccine integrity. During the COVID-19 pandemic, remote monitoring systems were key in keeping vaccines within the necessary cold chain conditions over transport and storage. This ensured they remained effective until they reached patients.

Food and Beverage Industry

In the food industry, companies like Nestlé depend on remote monitoring to ensure frozen goods stay within safe temperature limits from production to delivery. This technology plays a key role in preventing spoilage and foodborne illnesses so products reach consumers in ideal condition.

Agriculture and Livestock

In agriculture, remote monitoring is often used in greenhouses to create the best growing conditions for plants. For example, a greenhouse growing tomatoes might use this technology to maintain the perfect environment, ensuring a healthy and productive crop. Check out our agriculture software development page to explore more possibilities in this field.

Data Centers and IT Infrastructure

In data centers, companies like Google and Amazon rely on remote temperature monitoring to keep their servers cool. These systems help prevent overheating, which can cause hardware failures and service interruptions, keeping their massive data operations running smoothly without disruptions.

Smart Homes and Buildings

In smart homes and buildings, remote home temperature monitoring integrates with HVAC (heating, ventilation, and air conditioning) systems to optimize energy use. For example, in office buildings it adjusts zones based on occupancy for better comfort and lower energy costs. At home, smart thermostats like Nest help you stay comfortable and save energy.

With the added feature of air temperature monitoring, you can confirm that your remote home temperature monitoring system functions properly and maintains a comfortable environment.

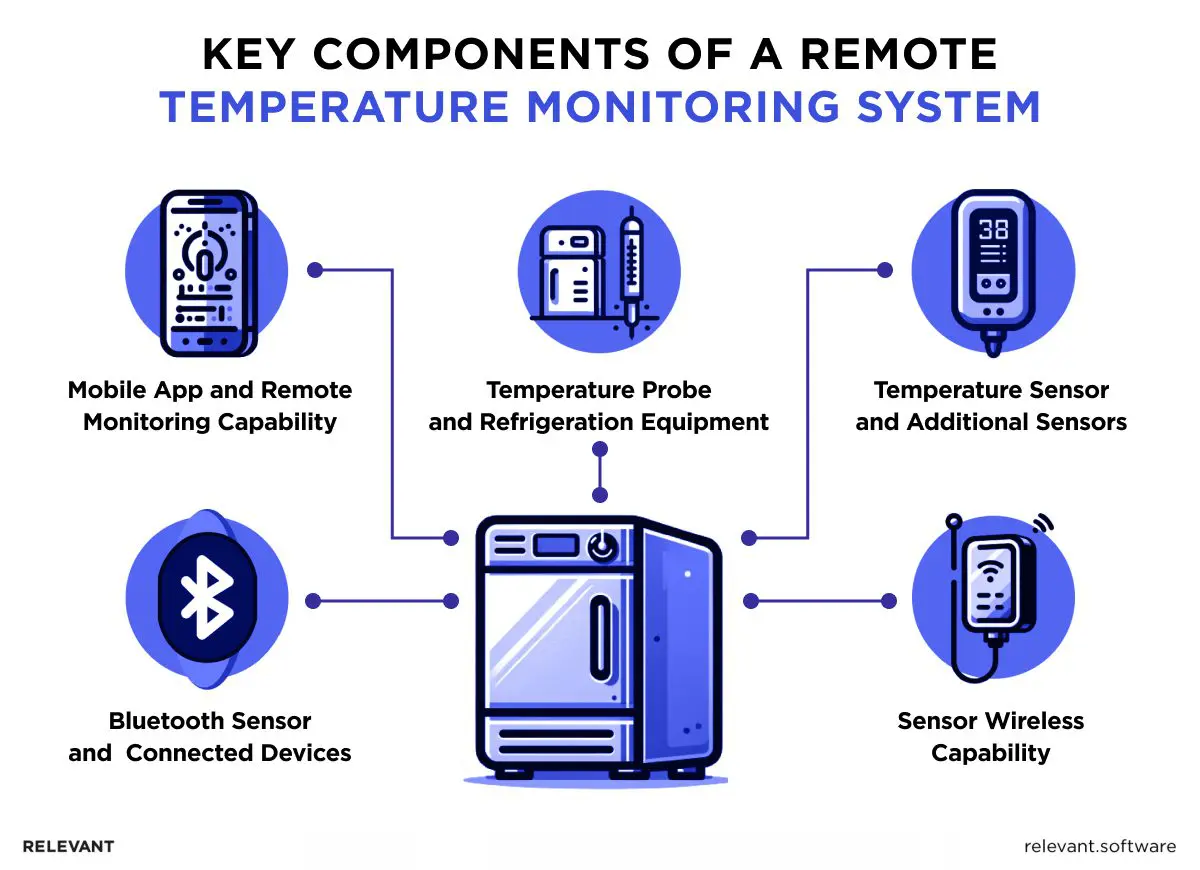

The Core Tools and Technology in Remote Temperature Monitoring

From the types of sensors used to the communication systems that transmit data, this section breaks down the essential components that keep everything running smoothly. After all, they’re what ensures your system operates as expected, day in and day out.

Sensors and Devices

Remote temperature monitoring starts with the sensors, which are the heart of the system. Standard sensors, effective in industries like food services and manufacturing, track temperatures from -40°F to 257°F. Thermocouples are often chosen for their ability to handle extreme conditions and their durability in harsh industrial settings. RTDs (Resistance Temperature Detectors) are preferred when precision matters, like in labs or manufacturing because they provide highly accurate and stable readings.

Wireless equipment, for example, with Wi-Fi temperature sensors and remote temp sensors, have gained popularity for remote temperature monitoring, too. These are particularly useful for applications like water temperature measurement in server rooms and other remote locations.

Infrared sensors, which measure heat from a distance without direct contact, are ideal for situations where it’s too risky or impractical to get close, such as monitoring machinery in production facilities.

Today’s remote temperature monitoring devices, such as high-temperature sensors, are the overachievers of the sensor world. They don’t just collect data—they offer real-time tracking, wireless connectivity, and alert systems that notify you immediately if something goes wrong.

Data Transmitters and Communicators

Once the sensors collect data, they need to be sent somewhere for analysis. This is where different communication methods come into play. Wi-Fi is perfect for nearby devices, Bluetooth works well for close quarters, and cellular networks are the go-to for those far-flung places where Wi-Fi can’t reach. These methods ensure you can access temperature data no matter where you are—next door or halfway across the planet.

With the convenience of remote temperature monitoring Wi-Fi, you can easily save, download, share, and review stored data, whether you’re at home or on the go. With options like wireless, Power over Ethernet (PoE), and Wi-Fi, you receive real-time alerts via text, email, or call, ensuring immediate notification of any changes in your environment. For instance, Monnit’s sensors can reach over 2,000 feet, reliably transmitting data even through 18 walls or more.

It’s not just about getting the data from Point A to Point B; it’s about making sure it doesn’t take a detour along the way. In fields like healthcare or pharmaceuticals, keeping your data safe from unauthorized access isn’t just important—it’s non-negotiable. That’s where secure communication channels and encryption protocols come in to keep the data safe and sound.

Data Analysis and Software Solutions

Gathering temperature data is just one piece of the puzzle; the true value emerges in its analysis. This is where data analytics plays a crucial role, especially in predictive maintenance. By evaluating temperature patterns, these systems can detect potential issues before they escalate into major problems. For example, if a piece of machinery consistently runs hotter than normal, the system can flag it for maintenance before a costly breakdown occurs.

There are also software platforms that consolidate all this data through real-time dashboards and automatic reports. This enables you to make informed decisions and take proactive steps to maintain optimal conditions in any environment you monitor.

Future Trends and Innovations

The future of remote temperature monitoring is closely tied to the rise of the Internet of Things (IoT) and Artificial Intelligence (AI). IoT already connects all sorts of devices, allowing them to share data in real time. When paired with AI, this data isn’t just stored—it’s analyzed and used in ways that become increasingly automated and intelligent.

Imagine a system where temperature sensors across a large facility are constantly sending data to an AI-powered platform. The AI learns what “normal” looks like for each piece of equipment or area, and when it detects an anomaly, it doesn’t just alert a human operator—it might automatically adjust cooling systems or even shut down a machine before it overheats. This predictive technology and automation lead to less manual work and quicker resolution of problems. In this way, we will not just make remote temperature monitoring better; we will redefine how we manage and protect critical spaces.

Sensor technology is another field where we’re noticing quick progress. The new sensors on the market are more accurate, tougher, and much more energy-efficient than their predecessors. For instance, advances in MEMS (Micro-Electro-Mechanical Systems) are leading to smaller, more reliable sensors that can be deployed in harsh environments where older models would fail.

Imagine a sensor that can run for years without requiring a battery charge while providing spot-on temperature readings, even in extreme conditions. This advancement creates many new possibilities, like their use in remote areas for environmental monitoring, where tracking ambient temperature changes over time is key. By leveraging advanced LoRaWAN technology, sensors deliver reliable and precise temperature data, which makes them valuable tools for industries such as agriculture, transportation, and healthcare. As technology advances, we can expect more innovations and applications in remote temperature sensor monitoring with LoRaWAN.

As sensors become more precise, they capture finer details, which is essential for medical research or high-tech manufacturing, where every measurement matters. These developments enhance remote temperature monitoring, making it more reliable, adaptable, and useful in many industries.

Curious about how IoT and AI in agriculture are farming game-changers? Check out our latest insights!

Our Case: Remote Monitoring System Development for a Fortune 500 Company

A leading Fortune 500 company sought our expertise in IoT product development to refine its web app. The app manages content for the robot and integrates with a Remote Monitoring System (RMS) to distribute this content efficiently across connected devices.

The client needed a system to monitor various devices remotely (e.g., CPU, RAM, disk, motors) and manage software installations and updates efficiently. It had to connect remote devices seamlessly, providing direct access to device consoles for quick troubleshooting. Ensuring robust security throughout these operations was critical.

Thanks to some dedicated effort, we’ve successfully launched a secure, simple-to-use remote monitoring platform. The system is designed to make it easy for anyone—whether technical or not—to manage, update, and maintain devices from anywhere with complete confidence.

Remote Temperature Monitoring: Final Thoughts

In 2023, the global market for temperature monitoring systems was valued at $1.43 billion. It’s expected to grow from $1.54 billion in 2024 to 2.93 billion by 2032, with an annual growth rate of 8.4%.

With such popularity, remote temperature monitoring is probably set to become even more advanced, giving us sharper insights and better control over the environments we rely on. However, the true value of temperature remote monitoring lies not just in the technology itself but in how it’s applied.

The best systems are those tailored to the specific needs of a business, taking into account the unique challenges and goals of each environment. Whether you’re focused on safety, efficiency, or just staying ahead of the curve, we’re ready to work with you to make it happen. Armed with our expertise in IoT, AI, and healthcare software development, we offer top-notch support and advice to help you build a system that’s not just up to today’s standards but is also future-proof—because who knows what tomorrow might bring? Contact us to start!

Hand-selected developers to fit your needs at scale! Let’s build a first-class custom product together.