IoT in Manufacturing: Turn Your Traditional Factories Into Smart Spaces

The emergence of IoT in manufacturing industry is transforming the very fabric of manufacturing by offering new levels of connectedness and efficiency that were once unthinkable. Picture a manufacturing floor where machines are not just pieces of hardware but elements of a smart network, equipped to regulate themselves, foresee maintenance needs, and optimize operations as things happen.

For those immersed in the industry, the integration of IoT transcends the basic concept of sensor-laden machinery or devices that talk to each other. It’s really about using a deep pool of data to identify insights that can lead to better and faster decision-making. This shift is significant: it means heightened production quality, minimal waste, and the flexibility to respond to market demands rapidly.

from 25 countries outsourced software development to Relevant

We provide companies with senior tech talent and product development expertise to build world-class software.

As IoT technology continues to evolve, it promises to reshape the roles and routines within the manufacturing sector. Engineers now have a wider, data-rich landscape for innovation, while managers get access to forward-looking tools to head off issues before they arise. Senior leaders receive a comprehensive, up-to-the-minute snapshot of the entire production process powered by data analytics.

This article about IoT for manufacturing isn’t just a cursory — it’s a roadmap for industry players gearing up to make strategic moves in this transformative period.

IoT in Manufacturing Industry: Revolutionizing Operations

Within the manufacturing world, “revolution” is a term we don’t use lightly — it’s saved for game-changing innovations that reshape how we create and produce. The Internet of Things, or IoT, falls into this category, combining the tactile realm of manufacturing with the digital world to take operational efficiency into new territory.

The Pivotal Role of IoT in Streamlining Manufacturing Processes

How is IoT used in manufacturing? There are broad and profound ways. Imagine an assembly line where every single part has a digital fingerprint, trackable at every step. Machines are no longer silent giants but are fitted with sensors that constantly check their pulse — tracking everything from their core temperature to their operational rhythms.

Now, let’s zero in on something as routine yet critical as equipment maintenance. In the past, this was a calendar event – every few weeks or months, regardless of need. It was a bit like giving your car a full service when all it needed was a top-up of windshield fluid. IoT shakes up this routine. It’s like having a fitness tracker for your machinery, measuring vital signs, and predicting hiccups before they happen. This means less guessing, fewer interruptions, and more getting it right the first time.

Utilizing IoT Sensors to Enhance Machinery Oversight

Sensors are the linchpins of IoT for manufacturing. They provide the eyes and ears on the factory floor, feeding into systems that assess the condition of machinery around the clock. This constant vigilance translates to data that can be used to predict wear and tear, not just react to it. The ability to anticipate and preemptively address potential issues fundamentally changes how maintenance is approached.

This approach is not simply about averting equipment failure; it also speaks to product quality. With precise remote monitoring, manufacturers can detect minute deviations in product specifications – often before they become visible to the human eye. This proactive quality assurance ensures that the integrity of the manufacturing process is maintained and the end product meets stringent standards.

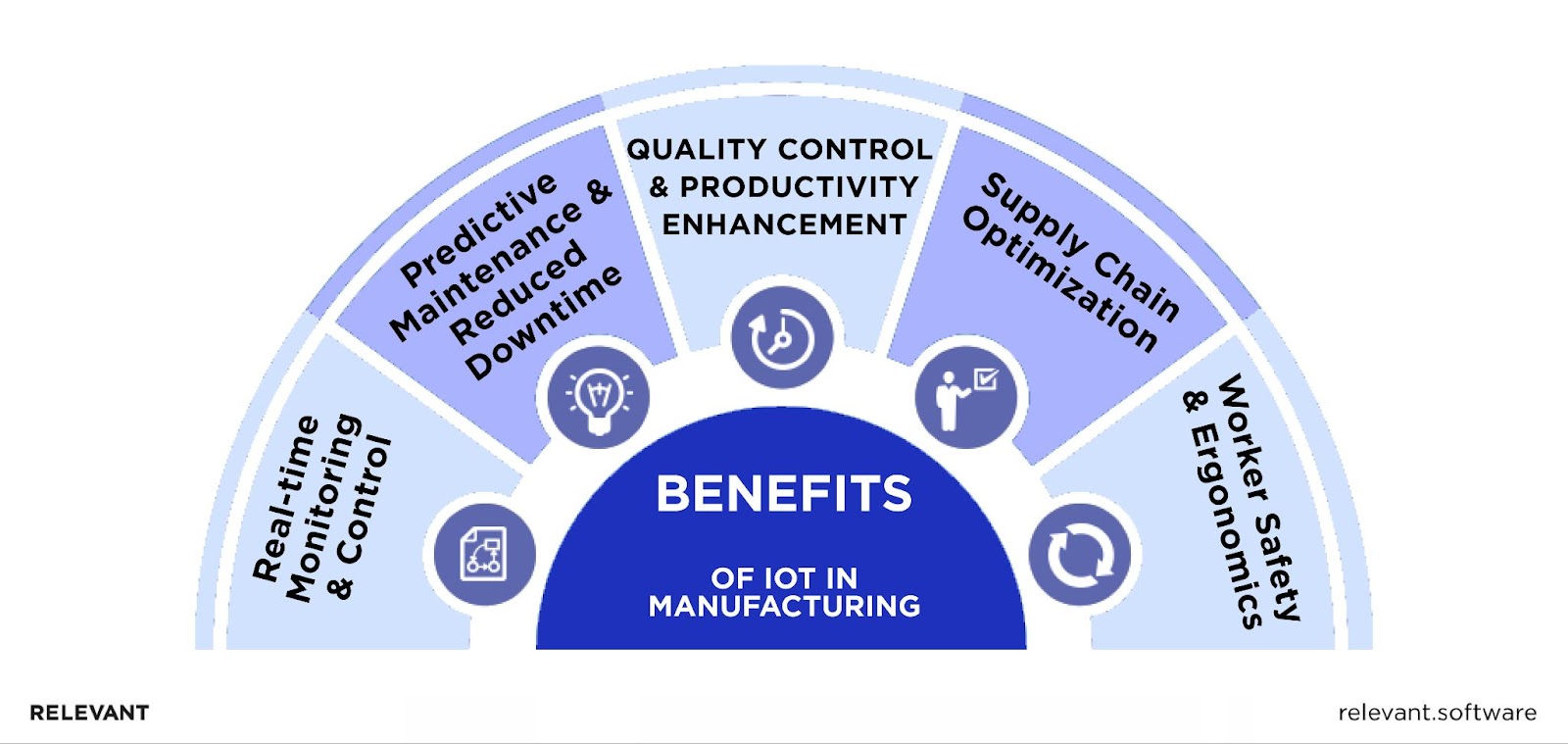

Benefits of IoT in Manufacturing

As we delve into the industrial ecosystem, IoT stands as a key enabler of smart manufacturing, offering a host of benefits that are both tangible and transformative.

Real-time Monitoring and Control

IoT shines when it comes to watching over production as it happens. Imagine having eyes on every part of the manufacturing process, with sensors and devices constantly reporting back on how machines and equipment are doing. This isn’t just gathering info for the sake of it. It’s about giving manufacturers — wherever they might be — the ability to make quick, informed changes. That kind of quick-footedness in tweaking operations is a game-changer; it means production stays in step with the latest needs and can quickly pivot to tackle any new challenges head-on.

Predictive Maintenance and Reduced Downtime

The saying “prevention is better than cure” gives IoT in manufacturing a whole new dimension. Through advanced data analytics, patterns that signal potential equipment failures are identified long before they manifest. This proactive stance, known as predictive maintenance, avoids a costly and reactive approach to repairs after a failure. Consequently, downtime — a perennial thorn in the side of production efficiency — is significantly minimized.

Quality Control and Productivity Enhancement

Quality control is another arena where IoT application in manufacturing makes its mark. By integrating IoT technologies, manufacturers can ensure that their products meet the highest quality standards. Real-time monitoring can catch deviations in product specifications, enabling immediate rectification. When it comes to productivity, IoT and automation are a match made in industrial heaven. They synergize to streamline production lines, cutting waste and ramping up output.

Supply Chain Optimization

IoT’s impact reshapes more than just the shop floor — it reaches out into the complex area of the supply chain. With the help of tracking tech and sensors, we’ve got eyes on everything now, from the journey of raw materials to the delivery of the final product. This kind of visibility is a game-changer for inventory control and gets forecasting right on the money, making logistics more streamlined and on-the-ball.

Worker Safety and Ergonomics

When it comes to people on the ground, IoT is also stepping up the game. We’ve got sensors now that keep an eye out for any nasty surprises in the work environment and wearable gadgets that help keep the crew out of harm’s way. It’s about more than just cranking out widgets; it’s about creating a workplace that’s as safe as it is smart.

To wrap it up, slotting IoT in manufacturing industries mix is like giving the whole industry a tech-fueled turbo boost. We’re talking about a big step forward in the way we look after production, quality, and the well-being of our workforce. And as these smart techs keep getting smarter, who knows how far they’ll take the manufacturing world next?

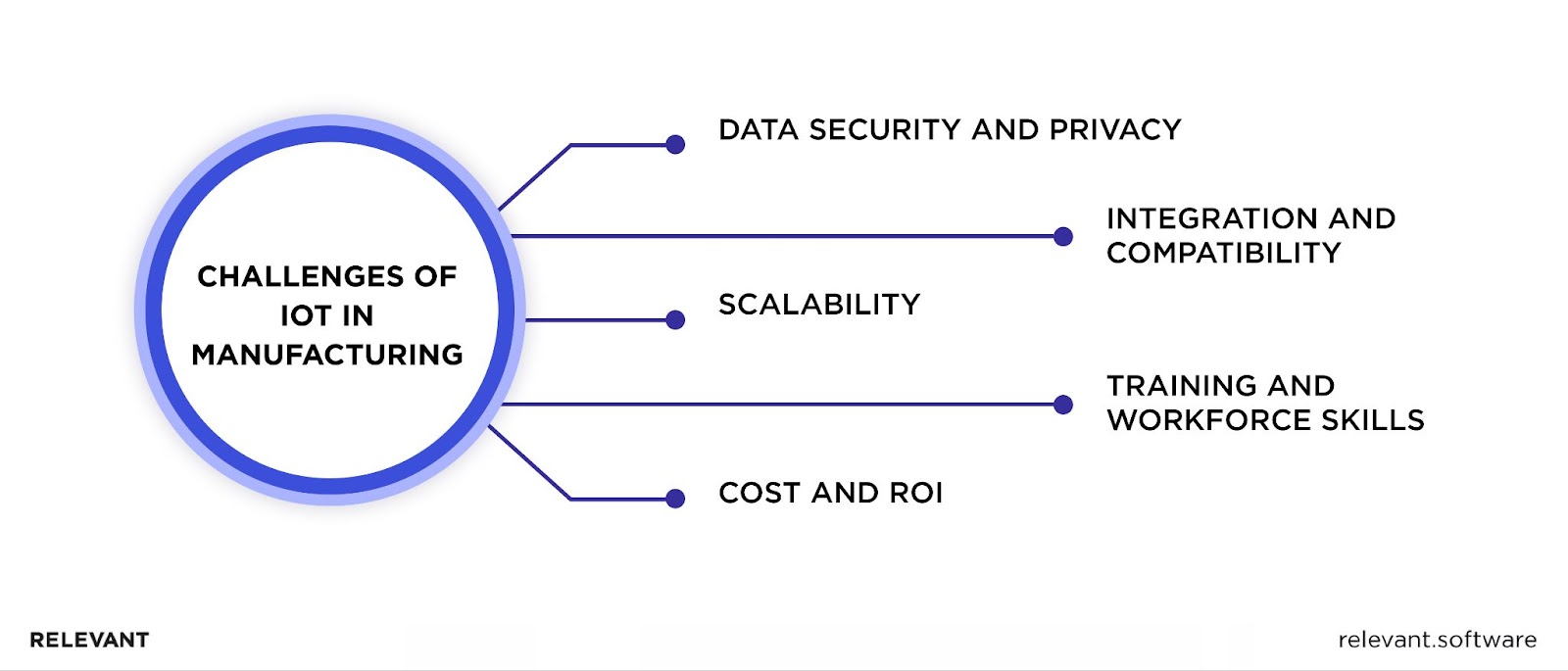

Challenges and Considerations of IoT in Manufacturing

Diving into the world of IoT for manufacturing, it’s clear that it’s not all smooth sailing. Adopting this tech does come with its own set of tough spots and head-scratchers. These challenges of IoT in manufacturing aren’t deal-breakers, but they’re definitely not to be swept under the rug. They need a thoughtful strategy and some serious know-how to tackle them right.

Data Security and Privacy

When we throw open the doors of our factories to the digital world, securing the flood of data becomes critical. With every new connection, the risk of cyber threats ticks up a notch. It’s essential for manufacturers to build a digital fortress that’s robust enough to shield today’s data and nimble enough to face tomorrow’s cyber challenges. This isn’t just a box-ticking exercise for compliance; it’s about making data security a core part of the IoT game plan from day one.

Integration and Compatibility

There’s also the challenge of getting new IoT devices to live with the old guard of legacy systems. It’s a bit like trying to have a smooth conversation between different generations — sometimes, things get lost in translation. The goal is to weave an IoT network that speaks the same language as all your tech, ensuring everything works in harmony and keeps the production line humming.

Scalability

And let’s talk growth for a second. As your manufacturing business expands, so will the mountains of data it generates. The IoT setup has to be ready to grow with you, flexible enough to handle an increasing load without causing data traffic jams. It’s not just about scaling up; it’s about smart scaling that allows you to slice and dice this data to keep you ahead of the competition.

Training and Workforce Skills

IoT technology introduces a level of sophistication to manufacturing operations that demands a skilled workforce. Workers must be trained not only on how to use IoT technology but also on how to interpret the data it provides. This skilling challenge is a significant consideration, as the effectiveness of IoT deployment is directly linked to the competence of the workforce handling it.

Cost and ROI

Finally, the financial aspect cannot be ignored. The initial investment in IoT technology can be substantial. Manufacturers must weigh this against the long-term benefits and savings it can bring. Calculating the return on investment (ROI) requires a comprehensive understanding of how IoT will streamline operations, reduce downtime, and improve product quality over time.

Future Trends of IoT in Manufacturing Industry

Manufacturers worldwide are now fully tuned into the transformative power of the Industrial Internet of Things (IIoT). To clear up any mix-up between IoT and IIoT, it’s important to draw a distinct line:

IIoT stands for the Industrial Internet of Things, and it’s essentially a specialized branch of the broader Internet of Things. It’s tailored specifically for industrial applications. Think of IIoT as the technological glue that binds together machines and data analytics in the industrial space to create “intelligent” manufacturing environments.

On the flip side, IoT is the umbrella term that generally refers to the network of devices used by consumers that connect to the internet, sharing data. So, while IoT is centered around consumer devices and everyday use, IIoT zeroes in on industrial processes, remote supply chain management, and operational efficiencies.

As we’ve moved into 2023, the traction for IIoT within the industry is only gaining momentum. Just last year, the IoT in manufacturing market was pegged at over $209 billion. Fast forward to projections for 2026, and we’re looking at a market potentially worth nearly $398 billion, expanding at a 17.4% yearly growth.

So, what’s fueling this growth? Let’s get into the specifics.

AIoT: Making IIoT Data Work Harder

The true gold in IoT applications in manufacturing isn’t the devices but the data they generate. By 2025, we’re staring at a data generation of 80B zettabytes by IoT devices – a fourfold jump from 2019. Yet, a staggering 73% of this data isn’t even used. But don’t worry- AIoT – the combination of AI and IoT, can transform overwhelming data into actionable insights, flipping the script from quantity to quality of data.

The Rise of Predictive IoT

Considering that equipment upkeep can be up to 70% of production costs, predictive IoT’s ability to forecast equipment issues before they happen is a big deal. Studies show that preventative maintenance can increase equipment uptime by 20%, reduce costs by 10%, and cut planning time in half. This is just the beginning, with predictive IoT set to expand further.

Digital Twins & Industrial Metaverse

Digital twins are transforming the way industrial products are crafted and cared for, with giants like Unilever using them to fine-tune product quality. And it pays off – McKinsey estimates manufacturers using digital twins can see up to a 10% revenue boost. Pairing these twins with VR in the industrial metaverse enables even more detailed predictive modeling. With 17% of manufacturers using digital twins (and planning to do so), this area is ripe for growth.

Smarter Sensors

Finally, sensors – the eyes and ears of IIoT – are evolving. The market for these ingenious devices is set to soar to over $41 billion by 2030, driven by the uptake of Industry 4.0 and the push for predictive maintenance. From the factory floor to automobile safety, smart sensors are becoming indispensable.

5G Capabilities

The leap from 4G to 5G is a giant stride in connectivity. With 5g technology, sensors can capture and transmit data at breakneck speeds. This isn’t about faster streaming or quicker downloads — it’s about the transformative impact on industries like manufacturing, where immediate data transmission can be the difference between a snag and smooth sailing.

IoT in Manufacturing: Final words

If the idea of integrating IoT into your manufacturing operations seems daunting, consider us your on-the-ground partner. Our team brings a wealth of practical know-how, not just theoretical advice. We’re all about action – rolling up our sleeves, getting into the thick of things, and delivering results that you’ll see on your production floor and balance sheets.

Think of us not just as consultants but as collaborators who are as invested in your outcomes as you are. We’ll help you sift through the noise, focus on what data matters, and put systems in place that keep your machinery humming and your risks managed.

Ready to give your manufacturing operations a digital edge? Get in touch. Let’s make those efficiency gains you’ve been reading about a day-to-day reality for your business.

Hand-selected developers to fit your needs at scale! Let’s build a first-class custom product together.